Wire Mesh vs. Fabric Screens: Which Offers Better Strength and Versatility?

Ever wonder the difference between wire mesh and fabric screens? They're used for different things, but which one is better and more helpful? Here, we will review wire mesh and fabric screens, so that you can learn what they’re good at and perhaps where they don’t excel.

Wire Mesh vs. Fabric Screen Endurance Contrast

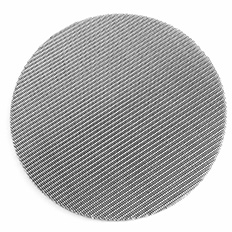

When we refer to longevity, wire mesh is generally much stronger than fabric screens. Wire mesh is constructed with metal wires which are woven to create a strong and highly reliable material. It holds heavy items and doesn’t get beat up easily by dings or bad weather.

Fabric screens are typically constructed of lighter materials, such as polyester or nylon. They can also be sturdy but more likely to rip and wear out. Fabric screens may be better suited to lighter work where strength is less of a concern.

The range of application can take advantage of the versatility of wire mesh and fabric screens.

Its strength also means it can be used for many things. It can go in fences, security screens, and even construction. Wire mesh can also be produced in various shapes and sizes, so it is suitable for a variety of uses.

Textile screens are sometimes used for decorative purposes, or to temporarily shield an area from the elements. They come in a variety of colors and patterns, so they’re popular for events or outdoor spaces. But fabric screens may not be tough enough for the hardest work as wire mesh.

Perception of Strength Variations If both stimuli are adjudged to be of equal strength some-thing different appears to be involved.

One major distinction between wire mesh and fabric screens is the strength of each. Wire mesh is generally significantly stronger thanks to the metal wires. They are designed to take more impact and provide better security and protection.

Fabric screens can also be strong of course but they can also lend themselves more to lighter uses where flexibility and breathability is what counts rather than outright strength.

Selecting Between Wire Mesh and Cloth Screens

When considering between wire mesh and fabric screens, consider what you want. If you need something that will haul heavy loads and provide security, wire mesh could be the answer.

If decorative or temporary stainless steel wire & mesh is more your style, fabric screens might fit the bill. Factor in how long you want it to last, how consistently you’re likely to use it, and how strong it needs to be, and make your selection.

Woven Mesh & Fabric Mesh Screens – “Pros & Cons”

There are good and bad points for both wire mesh and fabric screens stainless steel wire mesh so it’s a matter of personal preference and use. The stuff is tough and it lasts a long time, that’s a plus if you’ve got some intense work to do.

Although they are less durable than the screens from other materials, fabric screens are more portable and aesthetic and therefore suitable for decoration. But they may not be as sturdy or reliable as wire mesh.

In summary, you need to consider your requirements when making a choice between fabric and wire mesh screens. Whether one of these ss wire mesh two materials are needed to be very strong, or just nice looking, understanding the benefits that each has is important for many uses. Don’t forget to think about its durability, strength and usefulness in order to select the best choice for you.

Comments

Post a Comment