The Manufacturing Tolerances of Free Process PVC Board

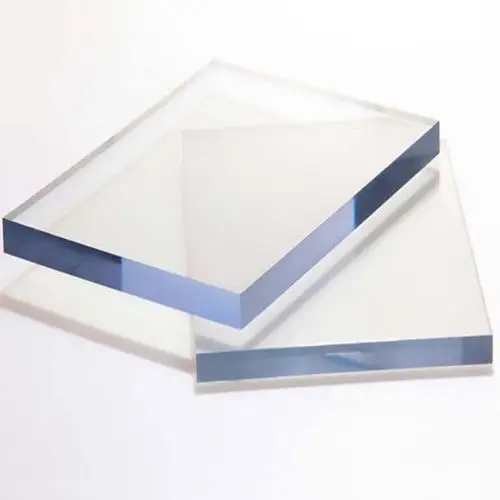

PVC boards have very large manufacturing tolerances. These tolerances ensure that each board is built consistently. This critical because even slight alterations in the way the boards are manufactured may influence the quality and usefulness of the boards.

Understanding why manufacturer tolerances are important when producing PVC boards, to help you get consistent quality per board. Surface or shape variances as small as a millimeter can affect how well a board works.

Ensuring the pvc board manufacturing of PVC boards is uniform and exact can also help guarantee that all the boards are just how they should be. By using the same board every time, manufacturers can ensure their product will perform well.

Using tight manufacturing tolerances makes sense in board pvc order to work efficiently and prevent waste. By making each board the same, there is less waste material (also improving the manufacturing processes).

It is very important to use the most sophisticated technology to produce the PVC Boards of a high quality with minimal wpc wall panel tolerances, it is important that each individual Board is of the same high quality. The most recent technologies ensure that each board is produced with exact specifications every time.

Comments

Post a Comment