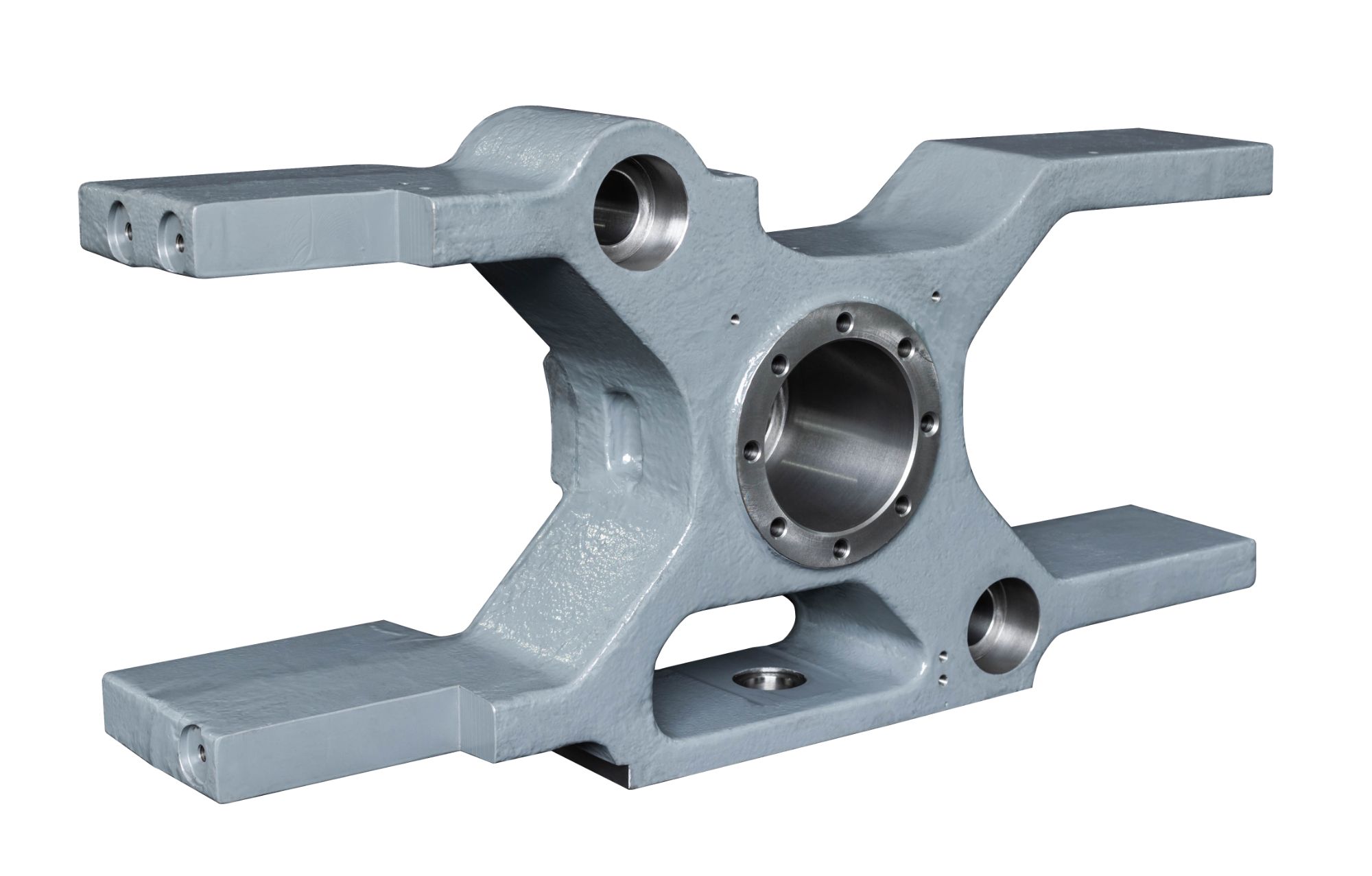

How a Reinforced Tail Platen Improves Clamping System Performance

Ever wondered how a powerful tail platen can alter the nature of a machine? In our conversation today, we are going to discuss how a reinforced tail platen will make the clamping systems of today better. This includes stability, accuracy, uniform pressure and mold alignment, durability, and effectiveness. Let's get started!

For Better Precision, More Stability

Stable is good when a a machine is running. A reinforced tail platen ensures that the machine remains steady by minimizing shaking and ensuring all parts remain in place during operation. This improved stability results in more accurate clamping together of parts—all of which stay in the right place throughout the process. This tends to minimize errors and provides better overall results.

Reduced Bend for Consistent Clamping Pressure

Bending, also known as deflection, is when a part deforms by bending under pressure. This can result in variable and unwanted clamping pressure and parts can move or be out of position. If we add stiffness to the tail platen, we can minimize this bending and maintain uniform clamping pressure. And that means clearer results – and less faulty parts in the products created.

Improved Mold Matching Performance and Better Part Quality

With the clamping pressure required to make good parts, the mold must remain aligned. A supported tail platen helps the mold to stay in place by offering reinforcement and stability, minimizing the risk of the mold shifting during the process of operation. That translates to better part quality and each piece being to the standards that they need to succeed.

Stronger for Long-Lasting Use

One huge advantage clamping unit in injection moulding machine of using a reinforced tail platen is longevity. It beefs-up the clamping system so that tail platen can take more wear and tear over the long haul. This means that it can continue to operate well for a long time without deteriorating. This robust build means the machine is a wise investment for any business.

Improving Efficiency of Clamping

Finally, a stiffened tail platen can improve the clamping action. The tail platen, by adding stability, minimizing bending clamping force unit, opening up mold alignment, and adding durability, means everything goes more smoothly. This means that parts can be manufactured more quickly and accurately. With this increased level of efficiency, businesses can better meet demands and stay on top in their industry.

In summary, a reinforced tail platen is imperative to enhance a clamping system. From greater stability and precision to reducing bending and improving mold alignment, it contributes a great deal to quality and efficiency. With the advanced reinforced tail clamping unit injection molding platen companies can expect improved performance and results, and as a result, greater productivity.

Comments

Post a Comment